The Role of Clinical Laboratory Testing in Healthcare

Clinical laboratory costs constitute less than 3% of total healthcare expenditures. However, approximately 70% of medical decisions are influenced by laboratory tests. These tests are essential for diagnosis, prognosis, risk assessment, preventive screening, and monitoring treatment effectiveness. Additionally, aggregated test data contribute to public health surveillance, performance measurement, and quality improvement. Clinical trial data further drive innovation, evidence-based medicine, and improved clinical guidelines, emphasizing the critical role of laboratory testing.

Impact of Laboratory Testing Quality on Healthcare

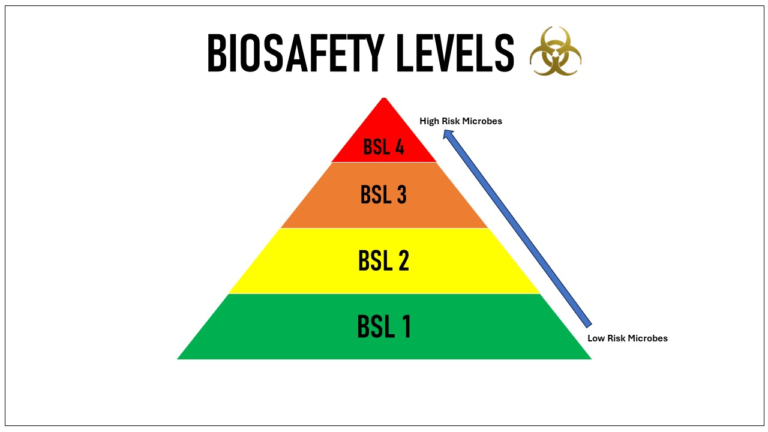

The accuracy and reliability of laboratory tests significantly impact patient care quality and healthcare costs. Errors in laboratory medicine can lead to serious patient care issues and increased costs. Laboratory results must be accurate, reliable, timely, and interpretable to meet the clinical decision-making needs within the healthcare system.

The Misconception About the Cost of Quality

A common perception is that high-quality services are expensive. However, in laboratory medicine, automation and advanced instruments have reduced analytical process variations and minimized errors. Most errors occur in the pre-examination phase, emphasizing the need for well-defined policies and processes outlined in a Sample Collection Manual. This manual should detail patient preparation requirements, sample collection procedures, volume specifications, appropriate tubes, and transportation conditions. Ensuring compliance with these guidelines prevents errors that can impact test results.

Shifting Focus from Blame to Systematic Improvement

Traditionally, laboratory errors were attributed to individual mistakes, leading to a culture of blame and punishment. However, studies such as Deming’s Red Bead Experiment have shown that most quality issues arise from flawed processes rather than individual staff members. Addressing systemic inefficiencies is key to improving laboratory quality and reducing costs.

Why Quality Principles Are Essential

Patients and clinicians should be the primary focus of healthcare services. Investing in quality processes requires effort and financial resources, but the cost of addressing failures due to poor quality is significantly higher. Proactive quality initiatives help reduce waste and enable laboratories to manage their budgets more strategically and effectively.

Understanding the Costs of Quality

Quality costs in laboratories can be categorized into two main types:

Good Quality Costs:

- Prevention Costs – Expenses incurred to proactively prevent problems before they occur.

- Appraisal Costs – Expenses incurred to identify and address issues before they escalate.

Poor Quality Costs:

- Internal Failure Costs – Expenses related to correcting errors before results are released.

- External Failure Costs – Expenses related to addressing errors after results have been issued, which are the most costly failures.

Types of Quality Costs

Prevention Costs

These costs focus on preventing problems before they occur. Examples include:

- Establishing a Quality Management System (QMS)

- Quality planning and improvement activities

- Training and competency assessments

- Validating laboratory processes before implementation

- Preventive maintenance

Appraisal Costs

These costs involve assessing service and product quality. Examples include:

- Ongoing competency assessments

- Tracking quality indicators

- Internal and external audits

- Instrument calibration

- Sample and reagent inspections

- Quality control (QC) processes and data evaluation

- Proficiency testing

Internal Failure Costs

These costs address failures while they are still under laboratory control. Examples include:

- Pre-examination errors (e.g., mislabeled samples, data entry mistakes)

- Invalid instrument runs

- Expired reagents and materials

- Retesting and equipment repairs

- Downtime due to system failures

External Failure Costs

These costs arise when errors reach customers or patients. Examples include:

- Incorrect or lost reports

- Customer complaints and service recalls

- Misdiagnoses leading to patient harm

- Legal actions and reputation damage

Budgeting for Quality in Clinical Laboratories

Cost of Good Quality (Preventive and Appraisal Activities)

- Preventive Activities:

- Quality planning for operations, inspections, and reliability

- Training programs for laboratory personnel

- Establishing service requirements for processes and reports

- Maintaining a robust Quality Management System (QMS)

- Continuous quality improvement initiatives

- Appraisal Activities:

- Regular competency assessments

- Verification and calibration of laboratory instruments

- Conducting internal and external quality audits

- Participation in proficiency testing programs

Cost of Poor Quality (Failure Costs to Avoid)

- Internal Failure Costs:

- Unnecessary work and inefficiencies

- Equipment downtime

- Retesting, specimen redraws, and correcting data entry errors

- Failure analysis and root cause investigations

- External Failure Costs:

- Handling customer complaints

- Correcting diagnostic errors

- Legal issues and malpractice claims

- Reputational damage affecting revenue

Understanding the Practical Impact of Quality Costs

A key example of appraisal activity is Quality Control (QC). If QC is performed too infrequently, malfunctioning instruments may go unnoticed, leading to invalid test results. For instance, if QC checks are reduced from daily to weekly, any errors occurring between QC tests may result in a week’s worth of unreliable data. This can necessitate re-evaluations, report retractions, and potential negative impacts on patient care, making failure management significantly more costly than preventive measures.

Identifying and Tracking Quality Costs

To effectively manage quality costs, laboratories must first assess current expenditures on quality-related activities. Identifying areas with high failure rates and addressing them through preventive measures can significantly reduce costs over time. Key strategies include:

- Listing and tracking good quality costs within the budget

- Identifying labor and material expenses related to quality improvement

- Recognizing non-conforming events (NCEs) and their financial impact

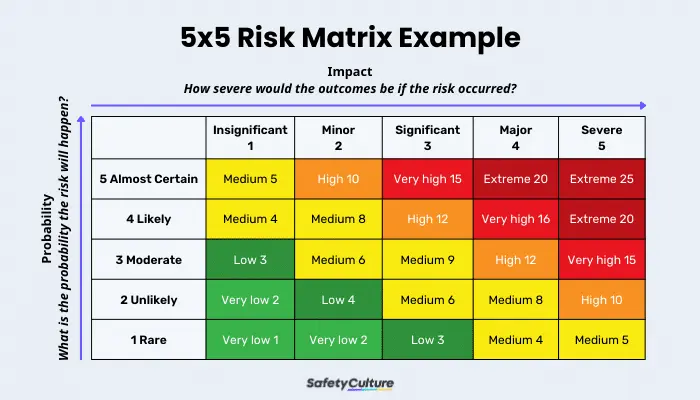

- Prioritizing high-severity failures that directly impact patient care

Calculating Failure Costs

Failure costs can be calculated by:

- Identifying key non-conforming events (e.g., lost reports, mislabeled samples)

- Determining the associated costs, including material and labor expenses

- Analyzing budget data to track expenditures related to quality failures

- Estimating the cumulative cost of recurring quality failures over time

Strategies to Reduce Failure Costs

Reducing failure costs requires a combination of preventive and appraisal activities to minimize waste and errors. A reactive approach to problem-solving is costly, whereas a proactive investment in quality reduces risks and enhances efficiency.

Four Key Strategies to Lower Poor Quality Costs:

- Track Quality Costs in the Budget – Understand how much is spent on quality activities.

- Identify and Reduce Non-Conforming Events – Focus on errors affecting patient safety and operational costs.

- Report Cost of Poor Quality (CoPQ) Data – Highlight failure costs in quality reports to drive improvement efforts.

- Educate Staff on Quality Principles – Promote organization-wide awareness of quality costs and encourage proactive quality management.

Achieving the Lowest Total Cost of Quality

A balance must be struck between good quality costs and poor quality costs. Many clinical laboratories operate below the optimal cost-efficiency point, where adequate resources have not been allocated to achieve the lowest possible total cost of quality. Investing in quality at the right levels leads to sustainable cost reductions and improved laboratory performance.

Conclusion

Rather than addressing quality issues only after failures occur, laboratories should implement strategic preventive measures. Integrating quality cost management into daily operations benefits the laboratory, patients, and the budget. A well-structured quality program not only reduces costs but also enhances efficiency and reliability, leading to better patient outcomes and improved overall healthcare quality.